Sizes: 1/2-6/4 thickness x 3-3 1/2″ widths x 3-12′ lengths

Applications: Paneling, flooring, furniture.

Defining Characteristics: Brown-grey color variations, hard wearing surface, occasional bolt holes.

Reclaimed white oak has been the most popular reclaimed wood, at least here in the northeast, from about 2007-2010, and remains in high demand now. Before 2007, most specifications for reclaimed oak were simply reclaimed oak and differentiation between red and white oak, were far less common. Reclaimed white oak is fairly common in Ohio, Pennsylvania and parts of New York and New England. Traveling further south one begins to see more red oak than white oak and further north into Canada and northern New England one finds more softwoods, as well as beech and maple. Although one occasionally finds oak in industrial structures, the majority of reclaimed white oak and most other hardwoods for that matter, come from barns. Aesthetically, reclaimed white oak is a porous grained hardwood like ash and chestnut. Because of the significant amount of character ranging from patina, wormholes, nail staining, checking, fleck, saw marks and knots, it lends itself well to rustic applications where a sense of history and age is desired. Whereas most woods contain some amount of yellow and/or red, white oak has a very neutral color tone ranging from beige to brown that tends to darken with age. Preserving the dark patina on the surface is not always necessary as the checks and wormholes which tend to be somewhat common usually contain the dark contrasting tone range designers look for. As with most barn woods, white oak is commonly found in one of three forms: joists, beams and boards. Boards and joists are suited to be planed smooth or with the original surface left intact to preserve the original saw marks. Beam sawn stock is often more desirable from a woodworking standpoint as the boards are flat and square off the saw and can be sawn to any thickness whereas board and joist stock are usually just 1” or 2” thick, with 3” somewhat less common. Although beam stock tends to be more consistent in color, both beam stock and board stock contain a fair amount of contrast both from one board to another, as well as within each board. Because of the high demand for reclaimed white oak and the challenge associated with obtaining quality material, many suppliers have tried to market new material, either standing dead or just character grade white oak instead of offering legitimate old growth reclaimed white oak. Since white oak is a slow growing (and hence tight grained) wood, these newer alternatives offer a reasonable substitute at a fairly significant discount for those who do not need the real thing. However, when buying reclaimed white oak, be very clear in what you want and make sure that you are not paying for a clever marketing campaign or dealing with a shady supplier who may try to pass off new material for old. When specifying or ordering reclaimed white oak, things to consider – percentage/type of defects including rot, extent of bug damage, splits, pockets, pegholes. Hard to dry/dryness. Normal character voids, bug channels, dimensions, etc. Original surface vs resawn. Quality of material. Sunken white oak, European oak, Barrel stave, newly reclaimed white oak, character grade new oak, old growth reclaimed white oak (barn, house or factory).

Reclaimed white oak has been the most popular reclaimed wood, at least here in the northeast, from about 2007-2010, and remains in high demand now. Before 2007, most specifications for reclaimed oak were simply reclaimed oak and differentiation between red and white oak, were far less common. Reclaimed white oak is fairly common in Ohio, Pennsylvania and parts of New York and New England. Traveling further south one begins to see more red oak than white oak and further north into Canada and northern New England one finds more softwoods, as well as beech and maple. Although one occasionally finds oak in industrial structures, the majority of reclaimed white oak and most other hardwoods for that matter, come from barns. Aesthetically, reclaimed white oak is a porous grained hardwood like ash and chestnut. Because of the significant amount of character ranging from patina, wormholes, nail staining, checking, fleck, saw marks and knots, it lends itself well to rustic applications where a sense of history and age is desired. Whereas most woods contain some amount of yellow and/or red, white oak has a very neutral color tone ranging from beige to brown that tends to darken with age. Preserving the dark patina on the surface is not always necessary as the checks and wormholes which tend to be somewhat common usually contain the dark contrasting tone range designers look for. As with most barn woods, white oak is commonly found in one of three forms: joists, beams and boards. Boards and joists are suited to be planed smooth or with the original surface left intact to preserve the original saw marks. Beam sawn stock is often more desirable from a woodworking standpoint as the boards are flat and square off the saw and can be sawn to any thickness whereas board and joist stock are usually just 1” or 2” thick, with 3” somewhat less common. Although beam stock tends to be more consistent in color, both beam stock and board stock contain a fair amount of contrast both from one board to another, as well as within each board. Because of the high demand for reclaimed white oak and the challenge associated with obtaining quality material, many suppliers have tried to market new material, either standing dead or just character grade white oak instead of offering legitimate old growth reclaimed white oak. Since white oak is a slow growing (and hence tight grained) wood, these newer alternatives offer a reasonable substitute at a fairly significant discount for those who do not need the real thing. However, when buying reclaimed white oak, be very clear in what you want and make sure that you are not paying for a clever marketing campaign or dealing with a shady supplier who may try to pass off new material for old. When specifying or ordering reclaimed white oak, things to consider – percentage/type of defects including rot, extent of bug damage, splits, pockets, pegholes. Hard to dry/dryness. Normal character voids, bug channels, dimensions, etc. Original surface vs resawn. Quality of material. Sunken white oak, European oak, Barrel stave, newly reclaimed white oak, character grade new oak, old growth reclaimed white oak (barn, house or factory).

Sizes: 3/4-4/4 thickness x 3-8″ widths x 3-12′ legnths

Applications: Flooring and paneling.

Defining Characteristic: 3/4-4/4 thickness x 3-9″ widths x 3-12′ lengths

Sunken cypress is pulled from the great southern swamps. It was either harvested or just fell in the swamp and has sat in the anaerobic conditions under the water for a century or longer. To the extent that the logs were originally cut by man, they were axe cut. There they sat for over one hundred years, absorbing the dark minerals of the swamp. It is all old-growth material, tight grain and richly colored.

But the colors vary considerably from rich red and golds to the green and browns absorbed from the swamp.

This wood supposedly came from a mid-nineteenth century church. Most of the

church was constructed of white pine with a very small amount of white oak

and this spruce sheathing. As with most churches I’ve seen in the past,

there was clearly a sincere effort to construct the structure with the best

available materials and the finest craftsmanship. Although this spruce was

not especially prized then, its heavy thickness and tongue and groove

milling make it atypical for sheathing from this era.

Application: this wood is very dark and very naily, making it ideal for the

right paneling application or even as flooring if some denting can be

tolerated.

Dimensions: thick 4/4 can be used as is or resawn into a very thin paneling.

Most is 7-9″ wide. Random length to 16′.

Defining characteristic: very dark and extremely naily make it very

primitive looking

During the heyday of the industrial revolution most of the 100 million acres of the original long leaf southern yellow pine forest was cut down. The logs were often transported to local mills via river. Along the way, as many as ten percent of them sank. These sinkers were usually dense young trees. Young trees have a higher percentage of live sap wood and therefore a higher percentage of water, making them heavier and more susceptible to sinking. Many of these logs were axe cut and some had a chevron cut into them to pull the turpentine out while they were still standing. The logs this wood came from were pulled from Cape Fear in South Carolina. Unlike heart pine from industrial timbers, sunken heart pine has been absorbing the minerals of the river bottom for over a hundred years. Black, green, brown and grey tones wash into the previously vibrant red and gold of virgin heart pine to create a muted, dark tone; while the characteristic grain of heart pine remains as bold as ever.

Often times you need to understand the structure in order to understand the

wood. In the case of a cooling tower, the purpose of the structure is to

cool the water vapor so it will condense and can once again be converted to

steam to power the turbines. The structure is designed to have as much

surface area as possible so that more water will condense. The structure is

extremely wood intensive and yet the pieces are all rather small for such a

large structure. I had never before seen a wood structure five stories tall

with the largest wood member a nominal 4×4. Another first was the copper

fasteners – every nail, screw, bolt and nut was copper. Iron is cheaper but

rusts out and with all the water condensing would fail relatively quickly.

The result is a copper green patina on every single piece of this wood.

Cracking good.

Sizes: primarily 4/4 with some 5/4, 6/4 and 8/4. Primarily 4-9″ wide and

8-12′ long.

Applications: ideal for flooring, as well as all other interior

applications.

Grade: character grade, sound tight knot. No nail holes, very limited

checking.

Defining characteristic: unusual coloration from being under water so long

Milling and texture options: planed surface Grain density: about average for

heart pine, not loose but not especially tight either.

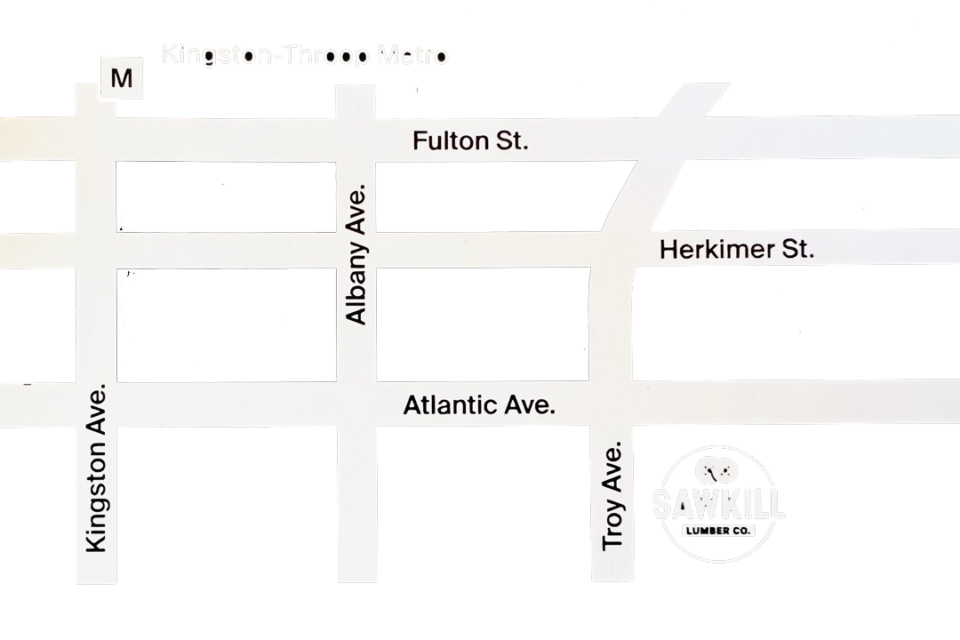

Our location at 71 Troy Avenue in Brooklyn includes a showroom, and a 3600 sf warehouse and wood shop. We are currently open for meetings by appointment. The space features a broad selection of over 40 antique, vintage and rare reclaimed woods.

(917) 862 7910

mailto:info@sawkill.nyc

Mon.-Fri. 9:00 – 5:30 pm

Sat. 10-4pm

71 Troy Ave.

Brooklyn, NY 11213

Please call in advance for appointment!

Getting There:

Train: A, C to Utica Ave. train stop. (approx. 8 min walk)

Car: Atlantic Ave. to Troy Ave. (1.5 mi. from Barclay Center)

Copyright © 2024 Sawkill NYC. All rights reserved.