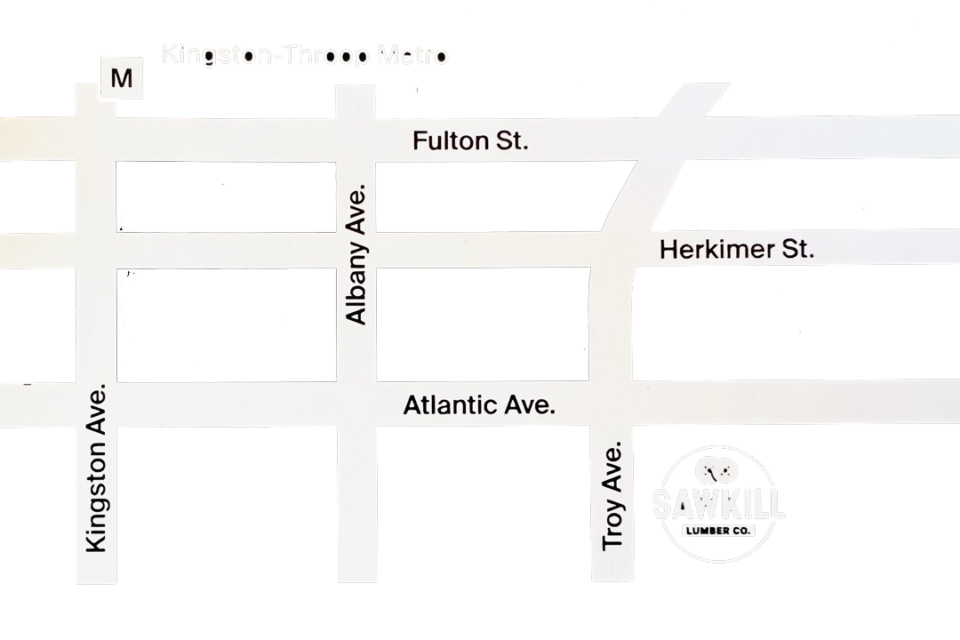

Sawkill Lumber joined with Menck Windows at the North American Passive House Conference 2016. The intersection of reclaimed woods – a certifiable ‘passive’ forest product – and energy efficient windows, was a triple-pane window made with reclaimed Redwood (salvaged from dismantled vinegar tanks), supplied by Sawkill Lumber and manufactured at the Menck Windows facility in the U.S.; just three hrs north of NYC in Chicopee, MA. Thanks to Menck for their leap into the process and putting the salvaged wood through their state-of-the-art milling equipment. Their acceptance of what’s otherwise a clear ‘defect’ in the wood was certainly stretched on this one. A remarkably technical, beautiful and uber-sustainable window emerged. The first one was installed at a Brooklyn passive house on the opening day of the conference.

reclaimed woods

Reclaimed woods eggstravaganza

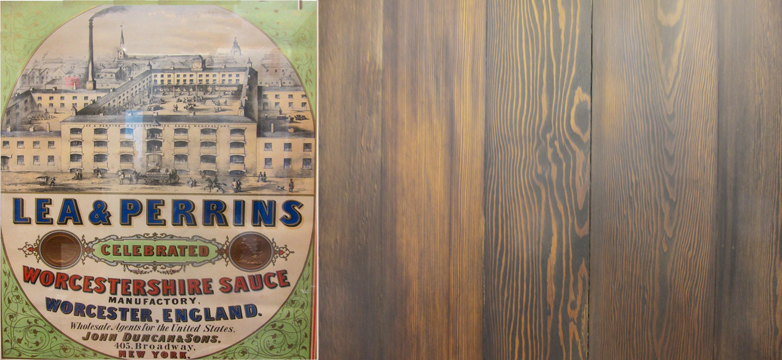

Worcestershire Doug Fir

Woods reclaimed from storage tanks are made from grade A lumber – often Oak, Cypress, or Redwood. Whether the water tanks that dot the city skyline or tanks used for wines, whiskey, pickles, and in the most current instance – Worcestershire Sauce.

This rare lot of Douglas Fir was recently salvaged from the Worcestershire Sauce tanks at the Lea & Perrins facility in New Jersey. Going back to the early 1800’s, when the sauce was invented (by accident), the company has gone through a handful of owners and locations (a third of the tanks were transferred from an old facility in Manhattan) until finally being acquired by Heinz, where the special sauce will be made in the midwest – though in Stainless Steel containers. Some say you can taste the difference when the sauce is seasoned within the wood tanks.

Doug Fir, named for the British explorer who identified the tree in the Pacific Northwest, the country’s second largest, yields wood with a clear dense figure and warm brown and red hues, that sometimes break out into psychodelic grain patterns. The old tanks can now go through renewal and into a range of beautiful building and design applications, including original surface and re-surfaced paneling, doors, floors and furniture.

Super Dry Woods

One quality measure that distinguishes antique lumber is century long air drying. There was no other choice before kiln drying technology was developing 150 years ago. And when it’s said that ‘they don’t make things like they used to’ – lumber is certainly one of them, and air drying is a significant factor in the quality difference.

Reclaimed antique lumber in all it’s forms is super dry – having resided as a building joist or timber for a considerable amount of time. This natural process prevents issues that occur in kiln drying.

- Brittle – Kiln dried wood is generally more brittle and prone to chipping. Sometimes referred to as ‘case hardening’, it can lead to the wood pulverizing if the KD process, if not properly controlled. Air dried lumber is more reliable to work, especially with hand tools.

- Internal Tensions – There are no internal tensions baked into air dried wood that could make lumber twist after it has been ripped. At other times, this may not be noticeable, or any worse for general use.

- Color loss – Short-cutting the seasoning process by kiln drying results in color loss. Kiln dried wood can lose as much as 20% of it’s color, as the kiln drying process kills some of the subtle hues in the grain, which further separates the aesthetic feel of freshly sawn and antique woods.

Kiln drying is faster, kills insects and can set pitch in some resinous softwood species, but none of these benefits apply to antique lumber. Old salvaged woods have remained in long-term dry storage and this investment of time and natural science yields good air dried lumber.

It’s common, however, for moisture to be picked up once the lumber is removed from a structure and then put into yard storage, so returning the woods to a slow kiln for a relatively short period (often under a week) – is needed to bring the moisture content back to equilibrium for an interior environment. The results are worth it.

Although there may be a place for both air and kiln drying methods, like a great piece of cheese or a glass of wine or hand-crafted whiskey, time is quality. We have tens of thousands of board feet of air dried hardwoods and softwoods at Sawkill, ready for a new era of dry and in some instances, wet environments.

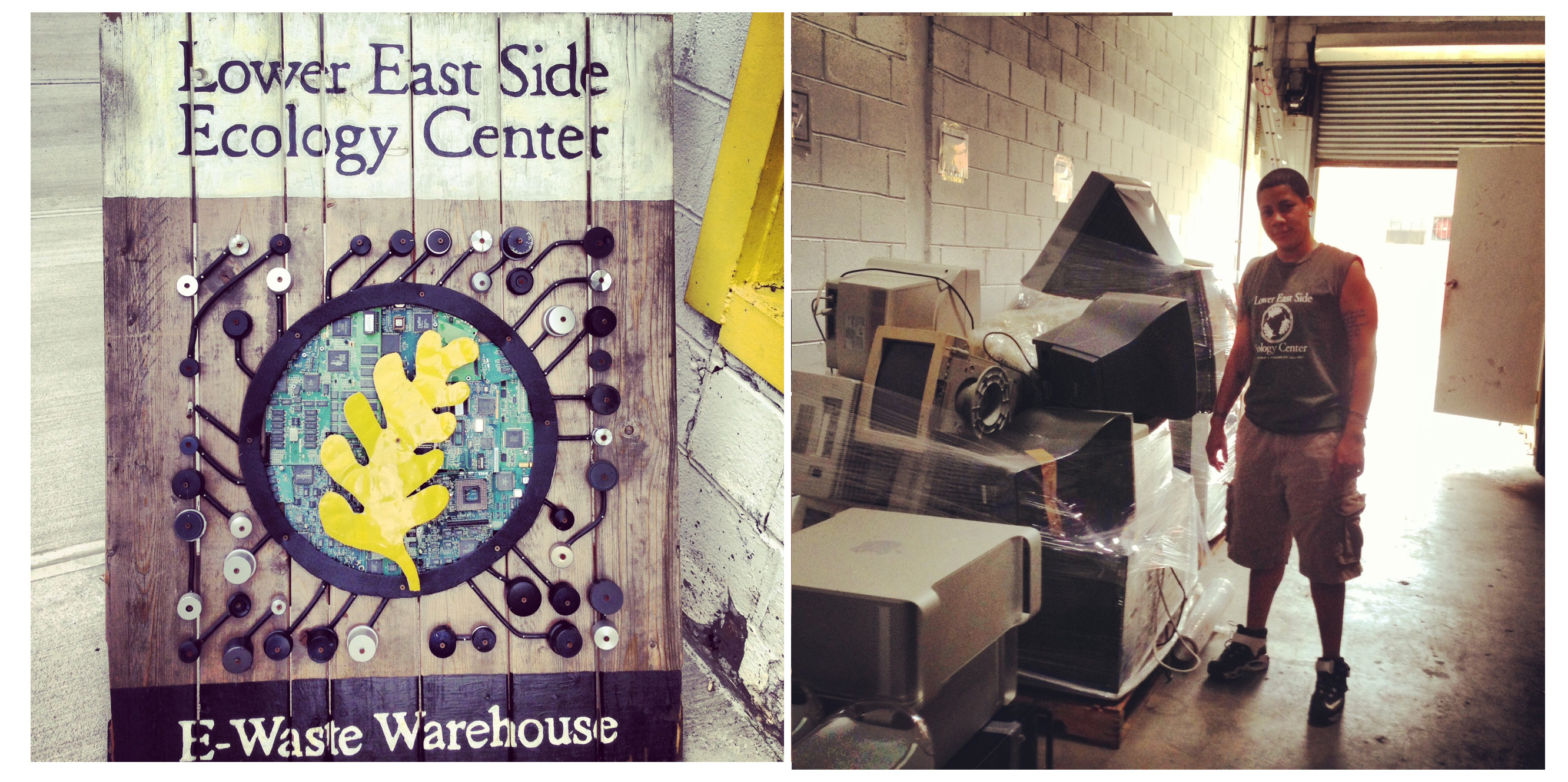

Lower East Side Ecology Center

The collatoral damage of the technology revolution happens before and after use. The manufacturing of a phone or computer involves a complex mix of toxic materials, sweatshop labor and non-renewable/non-recyclable/non-reusable resources. The troubles may only get sensed when it’s time to retire a product. There once were two options – hope that city services find a way to responsibly discard the item, or establish a personal archive of technology in an area storage unit.

The collatoral damage of the technology revolution happens before and after use. The manufacturing of a phone or computer involves a complex mix of toxic materials, sweatshop labor and non-renewable/non-recyclable/non-reusable resources. The troubles may only get sensed when it’s time to retire a product. There once were two options – hope that city services find a way to responsibly discard the item, or establish a personal archive of technology in an area storage unit.

Now there’s a third option. Lower East Side Ecology Center‘s electronic waste recycling is a unique and innovative program that allows residents to dispose of working and non-working electronics in an environmentally responsible way. People can bring unwanted electronics to e-waste collection events that take place in neighborhoods throughout the city, or drop off items at the Gowanus Brooklyn location.

The electronics warehouse will utilize some reclaimed wood from Sawkill Lumber, connecting materials that were once centuries apart.